Chiller and Cold Room Repair in Sharjah 0543747022 | Free inspection

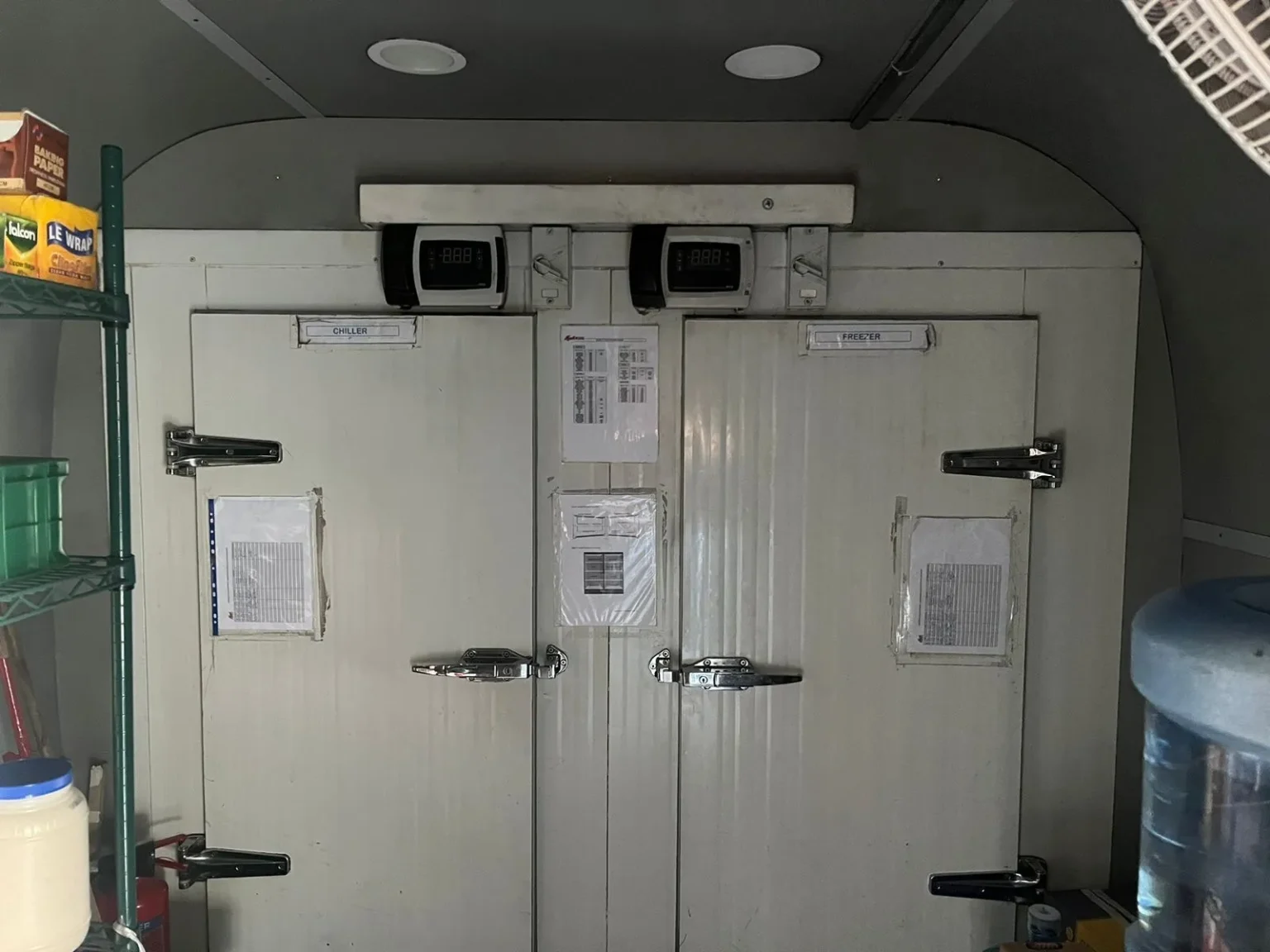

Cold Room Repair Services in Sharjah 0543747022

Importance of Maintaining Cold Room Functionality

When it comes to businesses in Sharjah, maintaining the functionality of cold rooms is not just important—it’s essential. The cold room acts as the heart of operations for many industries, particularly those dealing with perishable goods, such as restaurants, supermarkets, and food distributors. A dysfunctional cold room can result in spoiling products, unhappy customers, and significant financial losses.

Chiller and Cold Room Repair in Sharjah 0543747022

Reliable Storage for Perishables

Think about it: every day, restaurants rely on their cold storage to keep ingredients fresh. A few years ago, a local restaurant faced a crisis when their cold room malfunctioned overnight. By morning, they lost thousands of dirhams worth of seafood and dairy products. This not only strained their finances but also jeopardized their reputation.

To prevent such unfortunate incidents, regular maintenance is key. Here are some reasons why maintaining cold room functionality is crucial:

- Product Quality Assurance: Maintaining the right temperature prevents spoilage, ensuring that all goods are fresh when they reach customers.

- Energy Efficiency: A well-functioning cold room consumes less energy, helping businesses save on utility bills. For instance, upgrading insulation and fixing leaks could lead to a noticeable decrease in energy consumption.

- Regulatory Compliance: Certain industries have strict regulations regarding the storage of temperature-sensitive products. Failing to adhere to these standards could result in fines and legal repercussions.

- Operational Efficiency: A reliable cold room can optimize workflow. For example, when a restaurant’s cold room is fully operational, staff can easily store or retrieve ingredients without wasting time.

What are the Consequences of Neglect?

Neglecting to maintain cold room functionality can have detrimental consequences. Here are a few key issues that can arise:

- Increased Repair Costs: Small issues, if overlooked, can become major problems, leading to larger repair costs. A routine checkup could catch a minor refrigerant leak before it escalates into a costly compressor failure.

- Business Downtime: A malfunctioning cold room can halt operations, leading to lost revenue. A grocery store in Sharjah recently had to close for a day due to a cold room breakdown, resulting in not only financial loss but also customer dissatisfaction.

- Inventory Loss: The loss of products can happen quickly if temperatures rise. Perishables can spoil within a matter of hours, leading to waste and financial ramifications.

- Damaged Reputation: A business known for keeping high-quality products could suffer significant damage to its reputation following a product spoilage incident. Loyal customers may take their business elsewhere if they receive compromised foods.

Preventive Maintenance Tips

To help prevent these issues, businesses can take several proactive steps:

- Scheduled Inspections: Regular inspections, ideally every three months, ensure that all components are functioning optimally.

- Staff Training: Training staff on how to operate the cold room and monitor temperatures can make a significant difference. They should know how to identify early signs of malfunction.

- Regular Cleanings: Ensuring that the cold room is free of dust and debris can help improve efficiency. Regularly cleaning the condenser coils can enhance performance and reduce energy costs.

- Use of Monitoring Systems: Investing in temperature and humidity monitoring systems can alert businesses immediately if conditions go outside acceptable ranges.

In conclusion, understanding the importance of maintaining cold room functionality can make all the difference in ensuring smooth operations for businesses in Sharjah. By utilizing repair services and preventive maintenance, companies can safeguard their investments and continue delivering high-quality products to their customers. For inquiries on reliable cold room repair in Sharjah, companies can trust Emiratefix, reachable at 0543747022, to provide expert assistance and ensure optimal performance of their cold rooms.

Overview of Common Cold Room Issues

When it comes to cold room functionality, it’s essential to be aware of common issues that can arise. Recognizing these problems early on can save businesses time, money, and stress. Let’s dive into the most prevalent cold room challenges that business owners in Sharjah may face.

Unusual Increase in Energy Consumption

One of the first signs that something is amiss with a cold room can be an unexpected spike in energy costs. If a business notices that their monthly electric bill has increased significantly, it could indicate underlying issues with the cold room.

Understanding Higher Energy Costs

Several factors may contribute to unusual energy consumption in a cold room, such as:

- Faulty Components: Worn-out compressors or fans can cause the system to work harder than necessary, resulting in increased energy use.

- Poor Insulation: Insufficient insulation or damaged seals can allow cold air to escape, forcing the unit to compensate by using more energy.

- Dirty Coils: Condenser coils that are caked with dirt and debris can obstruct air flow, leading to inefficient operation.

For example, a bakery in Sharjah recently experienced a 40% increase in their energy bill. After a thorough inspection, they discovered that their condenser coils were dirty, and the door seals needed replacing. Once these issues were resolved, their energy consumption returned to normal levels.

Presence of Frost Buildup

Another common issue in cold rooms is the presence of frost buildup on surfaces, particularly around the evaporator coils. Frost accumulation can lead to various operational problems and should not be ignored.

Why Is Frost Buildup a Concern?

Frost can impact the overall efficiency of the cold room, and neglecting it can lead to:

- Reduced Airflow: Excess frost can block air from circulating properly, preventing even temperature distribution.

- Increased Energy Usage: As mentioned earlier, a struggling system often results in heightened energy consumption.

- Potential Damage to Components: If frost continues to build up unchecked, it can lead to component failures or even compressor burnout.

A restaurant owner in Sharjah once noticed frost rapidly forming on their cooling unit. After some research and advice from a repair professional, they learned that their unit was in need of defrost timer replacement. This simple fix not only remedied the frost problem but also improved energy efficiency.

Inconsistent Temperature Levels

Inconsistent temperature levels in a cold room can lead to significant complications, particularly in businesses dealing with perishable products. Maintaining a steady temperature is crucial for optimal storage conditions.

What Causes Inconsistent Temperature Levels?

Several factors can contribute to temperature inconsistencies:

- Thermostat Malfunction: A failing thermostat can lead to improper temperature readings, causing fluctuations in the cooling cycle.

- Refrigerant Leaks: A loss of refrigerant can diminish the cooling capacity and lead to significant temperature irregularities.

- Door Seal Issues: Worn-out door seals can allow warmer air to enter the cold room, making it difficult to sustain the desired temperature.

To illustrate, a convenience store had concerns that their drinks were not as cold as they should be, leading customers to complain. An inspection revealed the door seals were outdated and allowing warm air to seep in. After replacing the seals, the store noticed a marked improvement in temperature stability.

Tips for Addressing These Common Issues

To effectively manage cold room issues, businesses should consider:

- Regular Inspections: Schedule routine checks to identify problems before they escalate.

- Prompt Repairs: Don’t delay repairs when any of these issues are identified.

- Staff Training: Educate employees on the importance of monitoring temperature settings and recognizing warning signs.

In summary, being aware of these common cold room issues—unusual energy consumption, frost buildup, and inconsistent temperature levels—empowers business owners to act quickly and prevent further complications. By addressing these concerns, Sharjah businesses can ensure the optimal operation of their cold rooms while safeguarding their valuable inventory. For effective cold room repair services in Sharjah, contact Emiratefix at 0543747022 to get expert assistance.

Finding the Right Repair Service Provider

Having a reliable cold room is essential for many businesses, and when repairs are needed, finding the right service provider can make all the difference. In this section, we will discuss how to effectively research local cold room repair companies in Sharjah and the key factors to consider before hiring a repair service.

Researching Local Cold Room Repair Companies

The first step towards resolving cold room issues is conducting thorough research to find reputable repair companies. With so many options available, it’s important to sift through the choices to find a company that truly meets your needs.

Where to Begin Your Search

- Online Reviews: Websites like Google, Yelp, and local business directories can offer valuable insights from previous customers. Look for companies with high ratings and positive reviews, as these often indicate a history of excellent service.

- Social Media: Platforms like Facebook and LinkedIn can provide information about company services as well as customer feedback. Check community groups or forums dedicated to businesses in Sharjah for recommendations.

- Referrals: Asking coworkers or other local business owners can yield reliable recommendations. A restaurant owner in Sharjah once referred a trusted repair service to a fellow business owner, which led to a successful and swift repair.

- Local Listings: A quick search for “Cold Room Repair in Sharjah” will provide a list of local companies. Compile a shortlist of potential candidates before diving deeper.

What to Look For in Repair Companies

- Experience: Look for companies with years of experience in the industry, particularly those specializing in cold room repairs. A long-term presence often suggests expertise and reliability.

- Licensing and Certifications: Ensure the company has the necessary licenses and certifications to operate. This not only reflects their professionalism but also safeguards you from subpar work.

- Response Time: Some emergencies require immediate attention. In such cases, inquire about the typical response time for repairs. Companies that can provide prompt service are often more desirable.

- Service Range: Ensure that the company has experience with various cold room systems, including different brands and models. A versatile skill set can save you time and effort.

Factors to Consider Before Hiring a Repair Service

Once you’ve narrowed down your options, it’s essential to evaluate each company further before making a decision. Here are some key factors to consider:

- Pricing and Estimates: Request written estimates from multiple repair companies. Compare the costs, but don’t just choose based on the lowest price. Understanding the value of service is crucial. Sometimes, paying a little more for quality work can save you money in the long run.

- Guaranteed Work: An important consideration is whether the company provides warranties on their repair work. A company that stands behind its services usually reflects confidence in its expertise.

- Customer Service: When contacting the company, pay attention to their customer service. Are they responsive to your inquiries? Do they take the time to answer your questions thoroughly? A company that values customer communication often provides better service.

- Service Contracts: It can be beneficial to inquire about service contracts that provide ongoing maintenance and repairs. This proactive approach minimizes downtime and extends the life of your cold room.

- Emergency Services: Confirm whether the company offers 24/7 emergency services. A malfunctioning cold room can happen at any time, and knowing you have support when issues arise grants peace of mind.

In conclusion, finding the right cold room repair service provider in Sharjah requires thorough research and careful consideration of several factors. By taking the time to assess local companies, their reputations, pricing, and customer support, businesses can make informed decisions that ultimately protect their investments. For those looking for expert assistance, Emiratefix at 0543747022 is a trusted provider known for reliable cold room repair services, ensuring your cold room operates at its best.

DIY Maintenance Tips for Cold Room Repair

While having a professional service on speed dial is crucial for significant cold room repairs, many maintenance tasks can be handled in-house. Implementing a regular DIY maintenance routine ensures your cold room operates efficiently, prolongs its lifespan, and reduces the need for frequent repairs. Let’s explore three essential DIY maintenance tips: cleaning condenser coils, checking door seals for damage, and monitoring temperature settings.

Cleaning Condenser Coils

One of the most effective ways to maintain a cold room’s efficiency is to regularly clean the condenser coils. Dirty coils can significantly impact the unit’s performance, making it work harder to achieve the desired temperature.

Why Clean the Coils?

- Improved Energy Efficiency: Clean coils can reduce energy consumption by up to 30%, which translates into lower utility costs.

- Extended Lifespan: A well-maintained unit tends to have a longer operational life, avoiding premature breakdowns.

How to Clean the Coils:

- Safety First: Always unplug the unit or turn it off before starting any cleaning process.

- Rodent and Dust Inspection: Inspect the area around the coils for debris or buildup of dust and dirt, as this can obstruct airflow.

- Use a Vacuum: Gently vacuum the coils with a brush attachment to remove dust and loose dirt.

- Wash with Mild Detergent: If the buildup is significant, use a soft cloth or a brush with mild soap and water. Rinse thoroughly and ensure no moisture remains.

- Frequency: Aim to clean the coils every three to six months, depending on the environment and usage level.

Once, a local café in Sharjah saved a considerable amount on energy bills after they started cleaning their condenser coils regularly. Their repair costs plummeted, and the cold room ran more efficiently.

Checking Door Seals for Damage

Another critical maintenance area that often goes unnoticed is the door seals. Where cold air escapes, you’ll find warm air invading—this duo can wreck havoc on temperature control!

Why Inspect Door Seals?

- Preventing Temperature Fluctuations: Damaged seals can lead to inconsistent temperature levels in the cold room, causing products to spoil more quickly.

- Energy Loss: Poor seals drive up energy consumption, much like dirty coils.

How to Check and Repair Door Seals:

- Visual Inspection: Check for cracks, tears, or gaps in the rubber seals around the door frame.

- The Dollar Bill Test: Insert a dollar bill between the door and the seal. If you can easily pull it out with little resistance, it’s time for a replacement.

- Cleaning: Keeping the seals clean contributes to their longevity. Wipe them down with soapy water to remove dirt and debris.

- Replacement: If you find significant damage, contact a local supplier for a replacement. Many door seals can be easily replaced by the owner.

A warehouse in Sharjah faced frequent temperature fluctuations until they realized the door seals were compromised. After replacing them, they noticed enhanced temperature consistency and a reduction in operational costs.

Monitoring Temperature Settings

Lastly, diligent temperature monitoring is crucial in maintaining a cold room. A small change in temperature can greatly affect product quality.

Why Monitor Temperature?

- Quality Control: Consistently monitored temperatures ensure that sensitive inventories, such as pharmaceuticals or perishables, remain viable.

- Early Detection of Issues: By keeping an eye on the temperature settings, signs of malfunction can be spotted before becoming serious problems.

How to Effectively Monitor Temperature:

- Invest in a Digital Thermometer: Using a reliable thermometer with a visible display makes it easy to check temperature regularly.

- Set a Routine: Establish a daily or weekly routine for checking temperatures and logging them. This record can help identify trends and issues over time.

- Adjust Accordingly: Ensure that temperatures are set optimally based on the products being stored— typically around 0 to 4 degrees Celsius for perishable items.

- Alarm Systems: Consider a monitoring system that sends alerts if temperatures deviate from the set range. This feature can be invaluable in large operations where the cold room isn’t checked constantly.

An ice cream shop in Sharjah adopted a temperature monitoring system after suffering product loss due to unforeseen fluctuations. Their proactive approach significantly reduced waste and improved inventory management.

In conclusion, regular DIY maintenance tasks such as cleaning condenser coils, checking door seals for damage, and closely monitoring temperature settings can make a significant difference in the performance and efficiency of cold rooms. These proactive measures not only help maintain product integrity but also enhance energy savings, ultimately benefiting your business’s bottom line. For more complex repairs or professional assessments, the experts at Emiratefix are only a call away at 0543747022, ready to help with your cold room maintenance needs.

Hiring Professional Cold Room Repair Services

While DIY maintenance tasks can go a long way in ensuring your cold room runs smoothly, there comes a time when professional expertise is essential for effective repairs. Hiring a qualified cold room repair service not only addresses immediate concerns but also contributes to the long-term health of your refrigeration system. Let’s explore the benefits of professional repair services and the steps involved in their repair process.

Benefits of Professional Repair Services

Engaging a professional cold room repair service presents several compelling advantages. Here are a few key benefits that make this choice worthwhile:

- Expertise and Experience: Professional technicians possess specialized training and years of experience in diagnosing and resolving cold room issues. They have seen a wide range of problems and know the best solutions to implement. For instance, an experienced technician can quickly identify a refrigerant leak and resolve it before it causes more significant damage.

- Time-efficient Solutions: Professional services are equipped to handle repairs swiftly, minimizing downtime for your business. When a cold room malfunctions, time is money. A technician can often complete repairs in a fraction of the time it would take an untrained individual to troubleshoot.

- Quality Assurance: Certified repair services usually guarantee their work, meaning that if the problem persists after a repair, they will revisit the issue without additional costs. This type of assurance builds trust and confidence in the services provided.

- Access to Specialized Tools: Many repairs require specific tools or diagnostic equipment that the average business owner may not possess. Professionals come prepared with the necessary equipment to effectively diagnose and repair issues.

- Preventive Maintenance Recommendations: Beyond fixing immediate problems, professional technicians can provide valuable insights into maintaining your cold room for optimal performance. They can suggest preventative measures tailored to your specific business needs, helping you avoid future breakdowns.

A food distributor in Sharjah experienced frequent cold room issues. After hiring a professional service, they not only resolved their immediate concerns but also received useful tips on routine maintenance, which led to improved efficiency and consistency in their operations.

Steps Involved in Professional Repair Process

When you hire a professional cold room repair service, there is typically a systematic process followed to ensure thorough and effective repairs. Here’s what you can expect:

- Initial Assessment: The technician starts by conducting a comprehensive inspection of the cold room. They will evaluate the entire system, checking components like compressors, evaporators, temperature controls, and seals. This assessment helps pinpoint the root cause of the issues.

- Diagnostic Testing: Using specialized tools, technicians perform diagnostic tests on the equipment. They may check for refrigerant levels, measure electrical currents, or run checks on temperature sensors to ensure everything is functioning correctly.

- Reporting Findings: After completing the assessments, the technician will report their findings to you. They will explain what’s wrong, the potential causes, and the recommended course of action, including an accurate cost estimate for repairs.

- Obtaining Approval: Before proceeding with any repairs, a reputable service will seek your approval. Transparency is key here, as this step ensures you understand what repairs are needed and the associated costs.

- Performing Repairs: Once you give the green light, the technician will begin repairs. This may involve replacing faulty components, cleaning coils, sealing leaks, or addressing issues identified during diagnostics.

- Final Testing: After completing repairs, the technician will conduct thorough testing to ensure that the cold room is operating at the appropriate temperature and that all components are functioning as they should.

- Post-Repair Consultation: Finally, the technician will provide a brief consultation on best practices for maintaining your cold room. They may also suggest a maintenance schedule or regular check-ups to ensure functionality and efficiency.

In conclusion, hiring professional cold room repair services offers invaluable benefits, ensuring your refrigeration systems run smoothly and efficiently. From expertise and efficiency to long-term solutions and preventive maintenance tips, professionals play a critical role in safeguarding your business investments. For anyone in Sharjah seeking expert assistance, Emiratefix is ready to deliver high-quality cold room repair services at 0543747022, ensuring your cold storage needs are met with professionalism and reliability.

Cost of Cold Room Repair in Sharjah 0543747022

When it comes to maintaining cold room functionality, understanding the costs associated with repairs can help business owners budget effectively. The expenses for cold room repair services in Sharjah can vary widely based on several factors. In this section, we will discuss what influences repair costs and the typical price range you can expect when seeking professional help.

Factors Affecting Repair Costs

Several elements can impact the overall cost of cold room repairs. Here are the primary factors to consider:

- Nature of the Problem: The complexity of the issue plays a significant role in determining repair costs. Simple problems like cleaning condenser coils or replacing door seals may be relatively inexpensive, while more complex issues like compressor replacements or refrigeration leaks could be significantly higher.

- Type of Cold Room System: The design and model of the cold room can influence the cost of repairs. Systems that are custom-built or feature specialized components may require specialized knowledge and tools, which can increase labor and parts expenses.

- Labor Fees: The rates charged by technicians can vary based on their experience and the complexity of the repairs. Highly skilled professionals with extensive experience may charge a premium, but their expertise can save money in the long run by getting the job done right the first time.

- Parts and Materials: If parts need to be replaced, the cost of those materials can vary. Generic parts may be more affordable, whereas manufacturer-specific components might come with a higher price tag.

- Urgency of Repairs: If your cold room requires immediate attention, you may encounter additional costs associated with emergency services. Many repair companies charge a premium for after-hours or same-day services.

- Geographical Location: The local market and competition can also influence pricing. Companies operating in areas with high demand may charge more, while those in less saturated markets might offer competitive rates to attract customers.

For example, a bakery in Sharjah recently faced a minor repair issue that escalated into a major problem. Initially, they attempted to fix a small refrigerant leak, only to discover later that a compressor was failing, leading to higher repair costs than anticipated. This experience emphasizes the importance of timely inspections and repairs.

Average Price Range for Cold Room Repairs

Understanding the average price range for cold room repairs can help businesses allocate their resources effectively. While exact costs can vary based on the factors mentioned above, here are some general estimates:

- Basic Maintenance: Services such as cleaning the condenser coils or checking door seals usually range from AED 150 to AED 400. This is a cost-effective way to keep your cold room running efficiently.

- Minor Repairs: For small repairs such as thermostat replacements or minor gasket repairs, you can expect costs between AED 400 to AED 800. These repairs can usually be completed within a few hours.

- Major Repairs: If your cold room requires significant repairs, such as compressor replacements or extensive refrigerant work, the costs can range from AED 800 to AED 2,500 or more. These repairs often involve several hours of labor and may require specialized parts.

- Emergency Repairs: If you need immediate assistance and require emergency services, be aware that fees can increase by 20% to 50% compared to standard rates.

As a general observation, most businesses find it advantageous to invest in regular preventive maintenance, as this can help mitigate larger repair costs in the future. Developing a consistent maintenance schedule can help identify problems before they turn into costly emergencies.

In conclusion, understanding the factors affecting cold room repair costs and familiarizing yourself with average price ranges is essential for effective budgeting. For businesses in Sharjah, it’s vital to work with a trusted provider like Emiratefix, accessible at 0543747022, to ensure that your cold room remains in optimal condition without breaking the bank. Investing in professional repair services and regular maintenance can save significant costs in the long run while maintaining product quality and efficiency.

Preventive Measures to Avoid Future Cold Room Repairs

Once you’ve dealt with cold room repairs, the last thing you want is to face the same issues again. Taking proactive steps can greatly reduce the likelihood of problems recurring in the future. In this section, we will discuss the importance of establishing a regular maintenance schedule and the significance of monitoring temperature and humidity levels.

Regular Maintenance Schedule

Just like any machinery, cold rooms require routine checkups to operate at their peak efficiency. Establishing a regular maintenance schedule is an effective way to ensure your cold room remains reliable and efficient.

Why Regular Maintenance Matters

- Identifying Issues Early: Routine inspections can help identify potential concerns before they escalate into serious problems. For instance, a technician may notice a small refrigerant leak during a scheduled check. Addressing it promptly can save you time and money later.

- Extending Equipment Life: Regular maintenance contributes to the longevity of your cold room system. Well-maintained equipment is less likely to break down unexpectedly, leading to reduced repair costs over time.

- Optimal Performance: A periodic review of your cold room’s components, such as fans, compressors, and evaporator coils, helps maintain optimal performance, ensuring a stable environment for your perishables.

Creating a Maintenance Schedule

- Frequency: Ideally, schedule maintenance checks at least every three months or more frequently based on the volume of use. High-use environments, such as restaurants or grocery stores, may require monthly inspections.

- Professional Involvement: Work with a professional repair service to conduct these assessments. Professionals will have the expertise and tools necessary to carry out detailed inspections.

- Routine Tasks: Include tasks like cleaning condenser coils, checking door seals, and assessing refrigerant levels in your maintenance routine.

For instance, a grocery store in Sharjah that implemented a quarterly maintenance schedule not only enjoyed fewer breakdowns but also observed significant energy savings on utility bills. By being proactive, they could focus on their business without the looming threat of cold room malfunctions.

Monitoring Temperature and Humidity Levels

Another vital preventive measure is consistently monitoring temperature and humidity levels in your cold room. Fluctuations in these conditions can result in spoilage, decreased efficiency, and added stress on the cooling system.

Why Monitoring Matters

- Stability is Key: Maintaining proper temperature and humidity levels ensures that perishables remain fresh and compliant with safety regulations. For example, dairy products and fresh produce need specific conditions to remain viable.

- Early Detection of Problems: By closely monitoring these key variables, you can detect anomalies early on. A sudden rise in temperature might indicate a malfunction or a door that hasn’t sealed properly.

Effective Monitoring Practices

- Invest in Reliable Sensors: Utilize digital temperature and humidity sensors that provide real-time data. Many modern systems also feature alerts for deviations from set parameters.

- Log Data Regularly: Keep a log of temperature and humidity levels. This will help identify trends over time and spot unusual patterns that may warrant attention.

- Establish Parameters: Know the ideal temperature and humidity ranges for your specific inventory. For instance, most fresh produce thrives at temperatures between 1-4°C and humidity levels around 85-90%.

- Conduct Random Checks: While automated sensors are excellent, schedule occasional manual checks to confirm the data aligns. This way, you can catch discrepancies early.

Reflection of what happens when neglecting temperature checks can be illustrated by a local restaurant that lost an entire shipment of seafood due to a temperature spike. By integrating monitoring systems, they now maintain quality and avoid costly losses.

In conclusion, proactive measures such as establishing a regular maintenance schedule and closely monitoring temperature and humidity levels are key to preventing cold room repairs. By investing in these preventive strategies today, you can save significant headaches and costs tomorrow. For expert assistance and advice on maintaining your cold rooms, contact Emiratefix at 0543747022, ensuring that your cold storage needs are not just met but exceeded.

Conclusion

As we have explored throughout this article, the efficiency and reliability of your cold room play a crucial role in the success of your business operations. Whether you manage a restaurant, grocery store, or any enterprise that relies on precise temperature control, understanding the importance of timely cold room repairs and effective maintenance strategies cannot be overstated.

Recap of Importance of Timely Cold Room Repairs

Timely cold room repairs are not just about fixing a problem when it arises; they are about maintaining the integrity of your business. Here’s a recap of why addressing issues promptly is critical:

- Preventing Losses: A malfunctioning cold room can lead to spoilage and product loss, resulting in financial burdens. The cost of lost inventory far surpasses the expense of routine maintenance and repairs. For example, a local catering business recently faced a heartbreaking loss of high-quality ingredients due to a delay in addressing a minor refrigerant leak that escalated into a full compressor failure.

- Sustaining Quality: Consistency is vital when it comes to product quality, especially in food service and perishable goods. Regular repairs ensure that temperatures remain stable, preventing fluctuation that can compromise the freshness of items like meats, dairy, and produce.

- Improving Efficiency: A well-functioning cold room consumes less energy, positively impacting your utility costs. Regular repairs also prevent overworking the unit, extending its lifespan. A small cafe in Sharjah who invested in timely repairs noted a significant reduction in their energy bills, enabling them to redirect those savings towards other business enhancements.

- Regulatory Compliance: Many industries have strict regulations regarding temperature control for safety. Regular maintenance and swift repairs help ensure compliance, reducing the risk of penalties or legal issues.

In summary, understanding the value of prompt cold room repairs translates into smarter business practices and better outcomes.

Final Tips for Effective Cold Room Maintenance

To ensure your cold room remains efficient and reliable, consider these final maintenance tips:

- Schedule Routine Inspections: Establish a regular maintenance plan that can include professional inspections. A checklist can help you remember essential tasks like checking seals, cleaning coils, and ensuring all components function properly.

- Train Staff on Basic Functions: Educating your employees on how to operate and monitor the cold room can significantly minimize risks. A well-trained team can identify small issues before they become big problems.

- Utilize Technology: Take advantage of modern technology, like temperature and humidity monitoring systems, that provide real-time data. Many systems can send alerts directly to you if conditions fall outside appropriate ranges.

- Document Everything: Keep detailed records of maintenance activities, repairs, and inspections. This documentation can be invaluable when troubleshooting future issues and provides a thorough history for your equipment.

- Be Proactive in Adjustments: If you notice changes in temperature or product quality, act quickly. The sooner you address a concern, the less likely it will escalate into a larger problem.

- Invest in Professional Services: Don’t hesitate to contact professionals for repairs or advice. Having a reliable service provider, like Emiratefix, at 0543747022 can make a huge difference in the quality of care your cold room receives.

In conclusion, the repercussions of neglecting your cold room can be severe, but with timely repairs and a proactive approach to maintenance, you can safeguard your investment and ensure smooth business operations. By following the tips laid out in this guide, you’ll maintain an optimal environment for your perishables while minimizing costs and hassle. Ultimately, the stability and efficiency of your cold room contribute significantly to your business’s success, so take the necessary steps to keep it in top shape.

Comments (1)

[…] Chiller and cold room repair in Sharjah […]